How to Choose the Right Battery Assembling Factory for Your Customized Li-ion Battery Project

Selecting the right Battery Assembling Factory is a critical decision that impacts the performance, safety, and success of your product. Whether you need a Customized Li-ion Battery for an IoT Device Battery, a high-power pack for Robot&E-Mobility, or a reliable Medical Device Battery, the manufacturing partner you choose will determine your project's outcome. This guide provides a step-by-step framework to help you evaluate and select a factory that aligns with your technical requirements, quality standards, and business goals.

Key Considerations at a Glance:

- Technical Expertise & R&D Capability

- Production Capacity & Scalability

- Quality Management Systems & Certifications

- Experience with Your Target Application

- Supply Chain Stability & Vertical Integration

- Communication & Project Management

Step 1: Define Your Project Requirements Clearly

Before approaching any factory, have a detailed specification sheet. This should include:

- Battery Chemistry: Do you need a standard Li-ion Cylindrical Battery, a slim Li-Polymer Battery, or a ultra-safe LiFePO4 Battery?

- Performance Parameters: Voltage, capacity (mAh/Ah), discharge rate (C-rate), cycle life, and operating temperature range.

- Application & Environment: Is it for an Industrial Usage Battery in harsh conditions, a Consumer Electronics Battery requiring sleek design, or a critical Analyzer instrument?

- Customization Needs: Special shape, connector type, battery management system (BMS) requirements, and labeling.

- Regulatory & Certification Needs: Target market certifications (e.g., CE, UL, CB, UN38.3 for transport).

Step 2: Evaluate Technical Capability and R&D Strength

A top-tier Battery Assembling Factory is not just an assembler but a solutions provider. Look for:

- Dedicated R&D Team: A strong team capable of material research, cell selection, circuit design, and thermal management. For instance, Hypercell, with its team of doctors, masters, and senior engineers, focuses on new technologies like solid-state and sodium-ion batteries while solving specific challenges like high-rate discharge or extreme temperature performance.

- Prototyping and Testing Facilities: Can they quickly turn your concept into a functional prototype and validate it through rigorous testing (electrical, safety, environmental)?

- Application-Specific Experience: Proven track record in your industry segment. A factory experienced in Medical Device Battery production will understand biocompatibility and stringent reliability standards better than a general-purpose supplier.

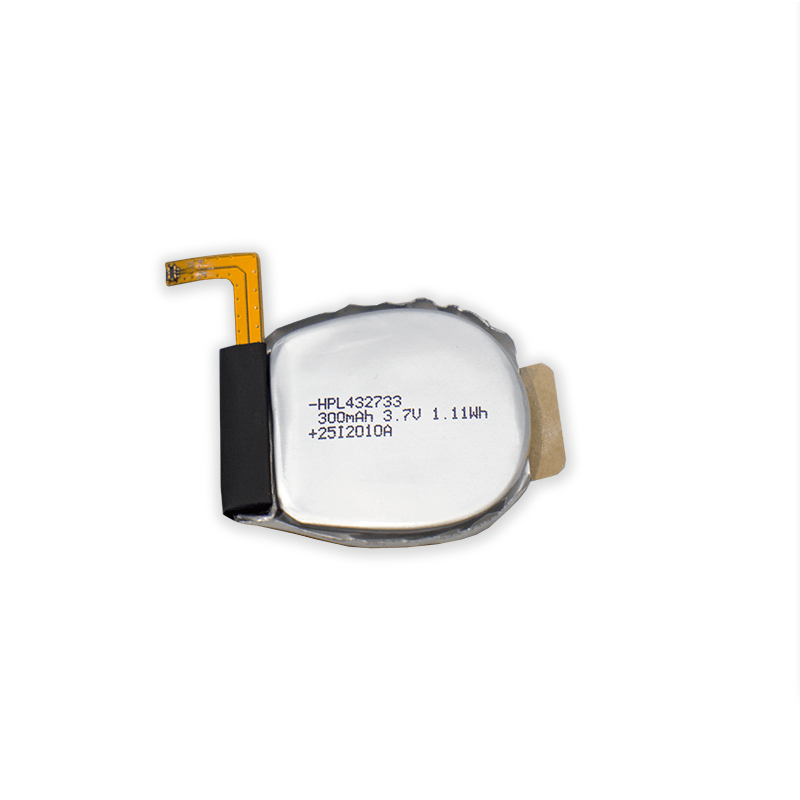

Example of a compact Li-Polymer Battery (HPL432733) suitable for space-constrained IoT Device Battery or wearable applications.

Step 3: Assess Manufacturing Scale, Quality Control, and Certifications

Scale without quality is a liability. Investigate the factory's operational backbone.

- Production Capacity: Can they meet your volume demands? Hypercell, for example, operates three factories in Guangdong with a daily output of 30MWh and over 1200 staff, indicating significant scale.

- Quality Management System (QMS): This is non-negotiable. A certified QMS like ISO9001:2015 ensures consistent processes. Hypercell is a qualified ISO9001:2015 and ISO14001:2015 enterprise, demonstrating commitment to quality and environmental management.

- Key Certificates: Look for relevant product and process certifications.

- CB Test Certificate: Facilitates global market entry.

- RoHS Certificate: Ensures compliance with hazardous substance restrictions.

- UN38.3 Test Reports (for Air/Sea Transport): Critical for safe and legal shipping of lithium batteries. Hypercell provides "Identification and Classification Reports" for both sea and air transport.

- In-House Testing: A robust factory will have in-house labs for safety tests (overcharge, short circuit, crush), performance tests, and environmental simulation.

Step 4: Analyze Supply Chain Stability and Vertical Integration

Recent global events have highlighted the importance of resilient supply chains. A reliable Battery Assembling Factory should have:

- Vetted Supplier Network: Long-term relationships with reputable cell suppliers (for Li-ion Cylindrical Battery or polymer cell cores).

- Vertical Manufacturing Capabilities: Control over key processes like BMS design, PCB assembly, welding, and pack assembly reduces dependency and improves quality control.

- Risk Mitigation: Strategies to handle raw material shortages or price fluctuations.

A high-capacity INR21700-13S10P pack, showcasing assembly capability for high-power applications like Robot&E-Mobility or large-scale Industrial Usage Battery systems.

Step 5: Review Communication, Support, and After-Sales Service

The partnership doesn't end at delivery. Evaluate their customer-centric approach.

- Responsive Project Management: A dedicated point of contact who understands technical details and provides regular updates.

- Technical Support: Assistance with system integration, BMS configuration, and troubleshooting.

- Warranty and After-Sales: Clear warranty terms and support for field issues.

- Company Ethos: Companies like Hypercell, with an 18-year history and a stated commitment to "green energy and sustainable growing," often align better with long-term, trust-based partnerships.

Case Study: Partnering with a Specialist - Hypercell

Let's apply this framework to Hypercell (www.hypercellbattery.com), a Battery Assembling Factory that exemplifies many of these criteria.

- Technical & R&D: Strong R&D team focused on new materials and technologies, offering solutions for special environments and specifications.

- Scale & Quality: 30MWh daily output, 1200+ staff, and certified ISO9001:2015/ISO14001:2015 systems.

- Application Expertise: Deep experience across Medical Device Battery, Consumer Electronics Battery, IoT Device Battery, Analyzer, and Robot&E-Mobility sectors.

- Product Range: Comprehensive portfolio including Li-ion Cylindrical Battery packs (e.g., INR18650 series), Li-Polymer Battery (e.g., HPL series), and LiFePO4 Battery solutions.

- Certifications: Holds CB TEST CERTIFICATE, RoHS certificate, and UN transport certifications.

For a project requiring a Customized Li-ion Battery for a new medical analyzer, Hypercell could provide the necessary regulatory understanding, high-precision manufacturing, and reliability testing.

Final Checklist Before You Decide

- Request and visit the factory (virtual or in-person) to audit facilities.

- Ask for detailed references from clients in similar industries.

- Request a Design for Manufacturing (DFM) review for your specific Customized Li-ion Battery project.

- Clarify all costs, including tooling, prototyping, testing, and unit pricing at different volumes.

- Review the contract thoroughly, focusing on IP protection, quality clauses, and liability terms.

Choosing the right Battery Assembling Factory is an investment in your product's future. By following this structured approach, you can form a partnership that delivers not just batteries, but reliable, innovative, and safe power solutions that give your product a competitive edge in the market.

For more information on custom battery solutions, visit: www.hypercellbattery.com | Email: sales@hypercellbattery.com | Tel: +86 755 1234 5678 (Shenzhen HQ)