How to Select the Right Customized Li-ion Battery for Your Application

In today's rapidly evolving technological landscape, powering your innovation is paramount. Whether you're developing a cutting-edge IoT Device, an agile Robot, or the next generation of E-Mobility solutions, the heart of your product's performance and reliability lies in its battery. As a leading China battery manufacturer, Hypercell has spent over 18 years mastering the art and science of Customized Li-ion Battery solutions. This guide will walk you through the critical steps to select the optimal battery for your specific needs.

Why Customization is Key

Off-the-shelf batteries often force design compromises. A Customized Li-ion Battery from a specialist like Hypercell ensures the energy source is engineered in harmony with your product's form, function, and operational demands—from a compact Medical Device Battery to a high-power Industrial Usage Battery.

Step 1: Define Your Core Requirements

Start by outlining your non-negotiable parameters. This forms the blueprint for your battery solution.

- Energy & Power Needs: Calculate the required capacity (Wh, mAh) and discharge rate (C-rate). A high-performance Robot may need a high-rate Li-Polymer Battery, while a long-life GPS Tracker might prioritize energy density.

- Physical Constraints: Define the available space (length, width, height). Hypercell excels at creating batteries in special shapes to fit unique industrial designs.

- Environmental Conditions: Specify operational temperature ranges, vibration, and humidity levels. For outdoor or industrial use, a robust LiFePO4 Battery might be ideal due to its thermal stability and safety.

- Lifecycle & Safety: Determine the expected cycle life and any critical safety certifications needed (e.g., for Medical Device Battery applications).

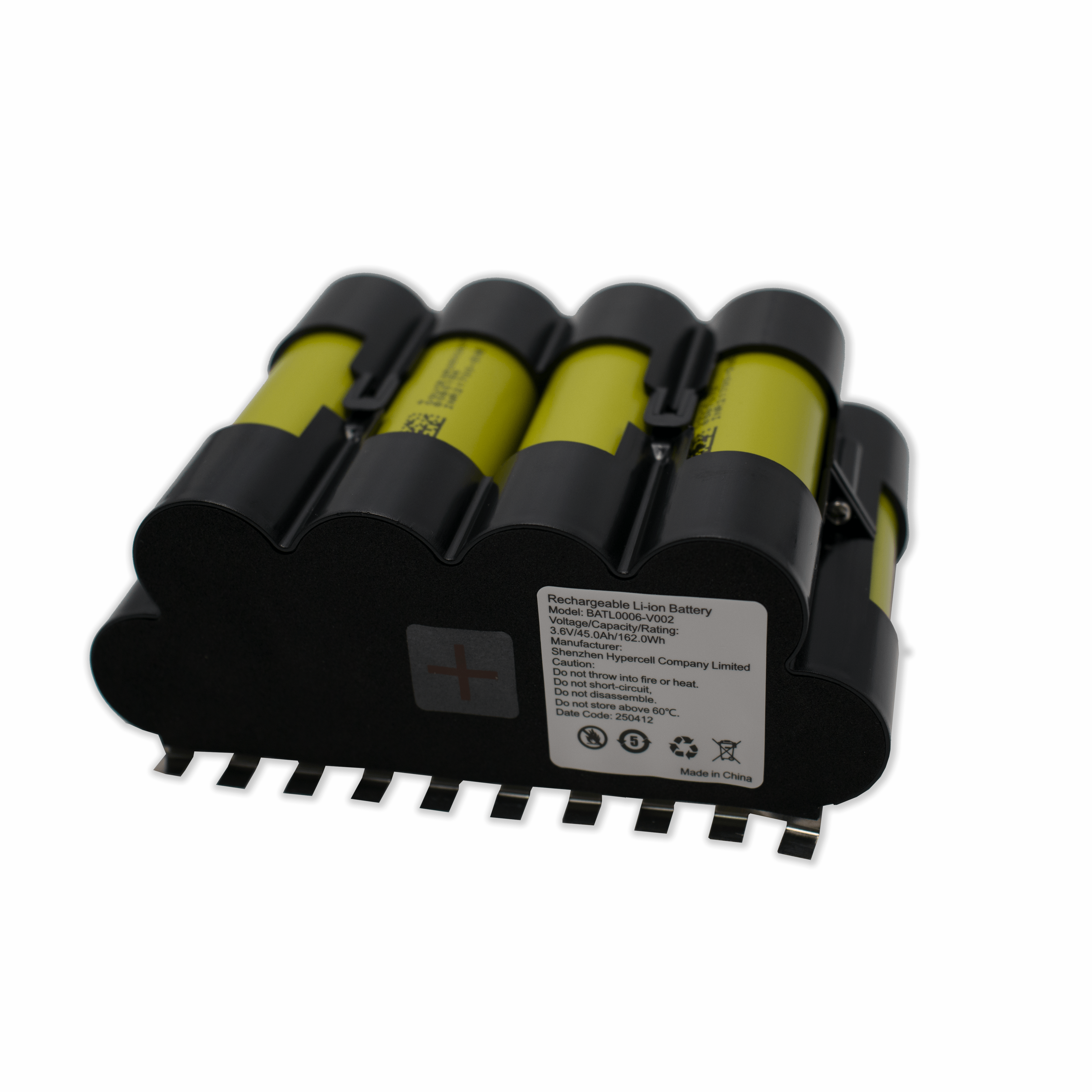

Example of a Customized Li-ion Battery pack (BATL0006-V002) designed for specific device integration.

Step 2: Choose the Right Battery Chemistry

Selecting the correct chemistry is fundamental to performance. Here’s a quick comparison from Hypercell's portfolio:

| Chemistry | Best For | Key Advantages |

|---|---|---|

| Li-ion Cylindrical Battery (e.g., 18650) | Consumer Electronics Battery, Power Tools, Light E-Mobility | High energy density, mature technology, cost-effective for high-volume production. |

| Li-Polymer Battery | IoT Device Battery, Wearables, Slim Medical Device | Flexible form factors, lightweight, can be made very thin. |

| LiFePO4 Battery | Industrial Usage Battery, ESS, High-safety E-Mobility | Exceptional safety, long cycle life, stable at high temperatures. |

Step 3: Partner with a Manufacturer with Deep Expertise

This is where Hypercell, a premier Hypercell battery-China battery manufacturer, stands out. Here’s what to look for in a partner:

- Strong R&D Capability: Hypercell's team of doctors, masters, and senior engineers tackles projects involving new materials, high/low-temperature performance, and fast-charge technology. They are also pioneering next-gen solid-state and sodium-ion batteries.

- Vertical Integration & Scale: With three factories in Guangdong and a daily output of 30MWh, Hypercell controls quality from cell to pack, ensuring supply chain stability for your Customized Li-ion Battery.

- Comprehensive Support: Their packing technology department provides integration support across industrial design, electronics, and testing.

Step 4: Prioritize Safety and Compliance

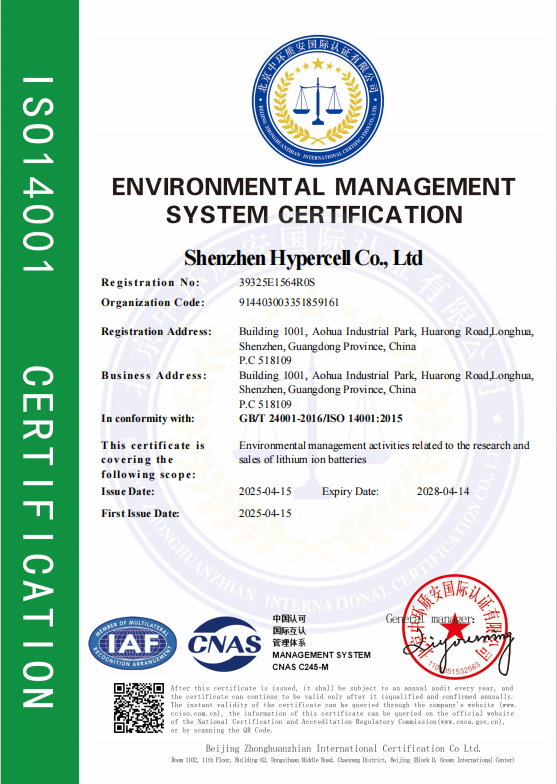

Never compromise on safety. Ensure your manufacturer adheres to international standards. Hypercell is a qualified ISO9001:2015 and ISO14001:2015 enterprise, with certifications including:

ISO9001

Quality Management

ISO14001

Environmental Management

CE-EMC

Electromagnetic Compliance

They also hold RoHS and UN38.3 transport certifications, crucial for global logistics of your Consumer Electronics Battery or Industrial Usage Battery.

Step 5: Prototype, Test, and Iterate

Engage with your manufacturer early in the design phase. Hypercell collaborates closely with clients to develop prototypes, conducting rigorous tests for performance, safety, and lifecycle under simulated real-world conditions for GPS Tracker, Robot, and Medical Device applications.

Conclusion: Power Your Vision with Hypercell

Selecting the right Customized Li-ion Battery is a strategic decision that impacts your product's market success. By following this guide and partnering with an experienced China battery manufacturer like Hypercell, you gain more than just a power source—you gain a technology partner dedicated to your product's excellence.

With 18 years of experience, a strong R&D team, and strict quality control, Hypercell is poised to deliver the high-quality, safe, and environmentally friendly battery solution your project demands. Visit www.hypercellbattery.com to start a conversation about powering your next innovation in IoT Device, E-Mobility, or beyond.