What is a Battery Assembling Factory? A Comprehensive Guide to Modern Battery Production

In the era of electrification, from Consumer Electronics to Industrial Usage and E-Mobility, the demand for reliable, high-performance batteries is skyrocketing. At the heart of this supply chain lies the Battery Assembling Factory. But what exactly does it do, and how does it transform raw materials into the power sources that drive our world? This guide delves into the intricacies of modern battery manufacturing, highlighting the role of leading manufacturers like Hypercell.

Key Takeaways:

- A Battery Assembling Factory is a highly specialized facility that designs, manufactures, and tests battery packs from individual cells.

- The process is critical for applications requiring Customized Li-ion Battery solutions, such as Medical Device Battery, Analyzer, and IoT Device Battery.

- Leading factories like Hypercell combine automation, stringent Quality Control, and advanced R&D to produce safe, efficient batteries.

- Certifications like ISO 9001, ISO 14001, RoHS, and CB are essential markers of a factory's reliability and commitment to standards.

The Core Functions of a Modern Battery Assembling Factory

A Battery Assembling Factory is far more than a simple assembly line. It is an integrated ecosystem of engineering, precision manufacturing, and rigorous testing. Its primary function is to take fundamental battery chemistries—like those found in Li-ion Cylindrical Battery, Li-Polymer Battery, and LiFePO4 Battery cells—and engineer them into complete, application-ready battery packs.

1. Design & Engineering

This initial phase involves understanding the client's specific needs for voltage, capacity, size (form factor), discharge rate, and environmental operating conditions (e.g., temperature). For a Robot&E-Mobility application, the design must prioritize high power output and mechanical robustness. For a sensitive Medical Device Battery, safety and long-term reliability are paramount. Factories with strong R&D capabilities, like Hypercell, utilize simulation software and prototype testing to optimize the design before mass production.

2. Cell Selection & Sourcing

The factory selects high-quality cells from trusted suppliers. The choice between an Li-ion Cylindrical Battery (e.g., 18650, 21700) and a Li-Polymer Battery (prismatic or pouch) depends on the design requirements for energy density, shape, and weight.

Figure: A high-power INR21700-13S10P battery pack from Hypercell, ideal for demanding Industrial Usage or E-Mobility applications.

3. The Assembly Process: Precision and Automation

The core assembly process typically includes:

- Cell Sorting & Matching: Cells are tested and grouped by voltage and internal resistance to ensure balance within the pack.

- Welding: Using laser or ultrasonic welding, cells are connected in series or parallel configurations to achieve the desired voltage and capacity. This is a critical step for safety and performance.

- Battery Management System (BMS) Integration: The "brain" of the pack. A quality BMS protects against overcharge, over-discharge, short circuits, and monitors cell balance. This is non-negotiable for Customized Li-ion Battery solutions.

- Enclosure & Packaging: The assembled module is housed in a casing that provides mechanical protection, thermal management, and sometimes IP-rated ingress protection.

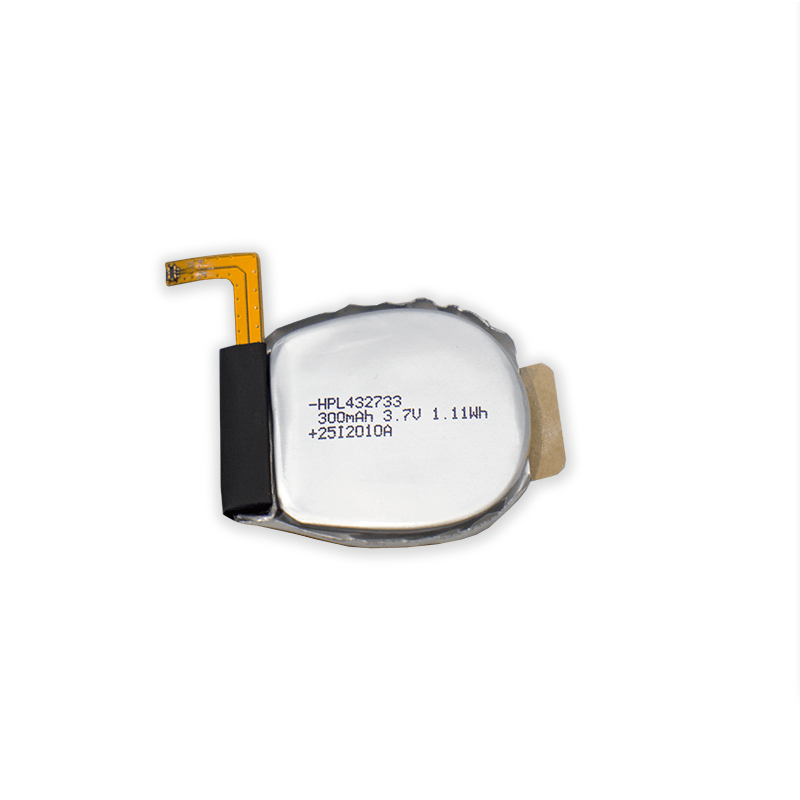

Figure: A compact HPL432733 3.7V300mAh Li-Polymer Battery, showcasing the sleek form factor possible with pouch cell assembly, perfect for compact IoT Device Battery or Consumer Electronics.

4. Testing & Quality Assurance (The Hypercell Standard)

This is where a reputable factory separates itself. Every batch undergoes a battery of tests:

- Electrical Testing: Capacity verification, cycle life testing, internal resistance measurement.

- Environmental Testing: Operation in high/low temperature chambers, humidity tests, vibration, and shock tests to simulate real-world conditions.

- Safety Testing: Short-circuit, overcharge, nail penetration, and crush tests.

Hypercell, as a qualified ISO9001:2015 and ISO14001:2015 enterprise, embeds quality control at every stage. Their strict compliance with international management systems ensures traceability and consistency. Furthermore, certifications like RoHS (restricting hazardous substances) and CB Scheme (international electrical safety) provide global market access and peace of mind for clients.

Why Choose a Specialist Factory Like Hypercell?

With over 18 years of experience and a daily output of 30MWh, Shenzhen Hypercell Co., LTD exemplifies the modern, advanced Battery Assembling Factory. Here’s what sets them apart:

Deep Application Expertise

Hypercell’s solutions are tailored for specific industries. Whether it's a high-reliability Medical Device Battery, a high-rate discharge pack for an Analyzer, or a durable Industrial Usage Battery for tools, their engineering team understands the unique demands.

Strong Vertical Integration & R&D

With a strong R&D team of doctors, masters, and senior engineers, Hypercell invests in new material and new technology. They are actively researching next-generation solutions like solid-state battery and sodium-ion battery technology, future-proofing their offerings.

Full-Scale Customization Capability

Beyond standard models, Hypercell excels at creating Customized Li-ion Battery solutions. They can develop batteries with special shapes, wide temperature ranges (e.g., -40℃ to +85℃), and high specific capacity to fit the most challenging design constraints.

Figure: The INR18650S 3.6V2900mAh Li-ion Battery from Hypercell, engineered for wide temperature operation from -40℃ to +85℃, demonstrating advanced material science for extreme environment applications.

Industry Trends and the Future of Battery Assembly

The Battery Assembling Factory of the future is evolving rapidly. Trends include:

- Increased Automation & AI: For higher precision, yield, and data-driven quality prediction.

- Sustainability Focus: Factories like Hypercell, with ISO 14001 certification, are optimizing for energy efficiency and recyclability.

- Demand for Application-Specific Packs: The growth of Robot&E-Mobility, IoT Device Battery, and renewable energy storage is driving need for highly specialized, smart battery systems.

Partner with a Trusted Battery Assembling Factory

Selecting the right Battery Assembling Factory is a strategic decision that impacts product performance, safety, and time-to-market. Hypercell stands as a proven partner with the scale, expertise, and certifications to deliver.

Explore Hypercell's Capabilities: Visit their official website at www.hypercellbattery.com to learn more about their Li-ion Cylindrical Battery, Li-Polymer Battery, and LiFePO4 Battery solutions, or to discuss your Customized Li-ion Battery project.

Hypercell – Powering Innovation with Reliability.